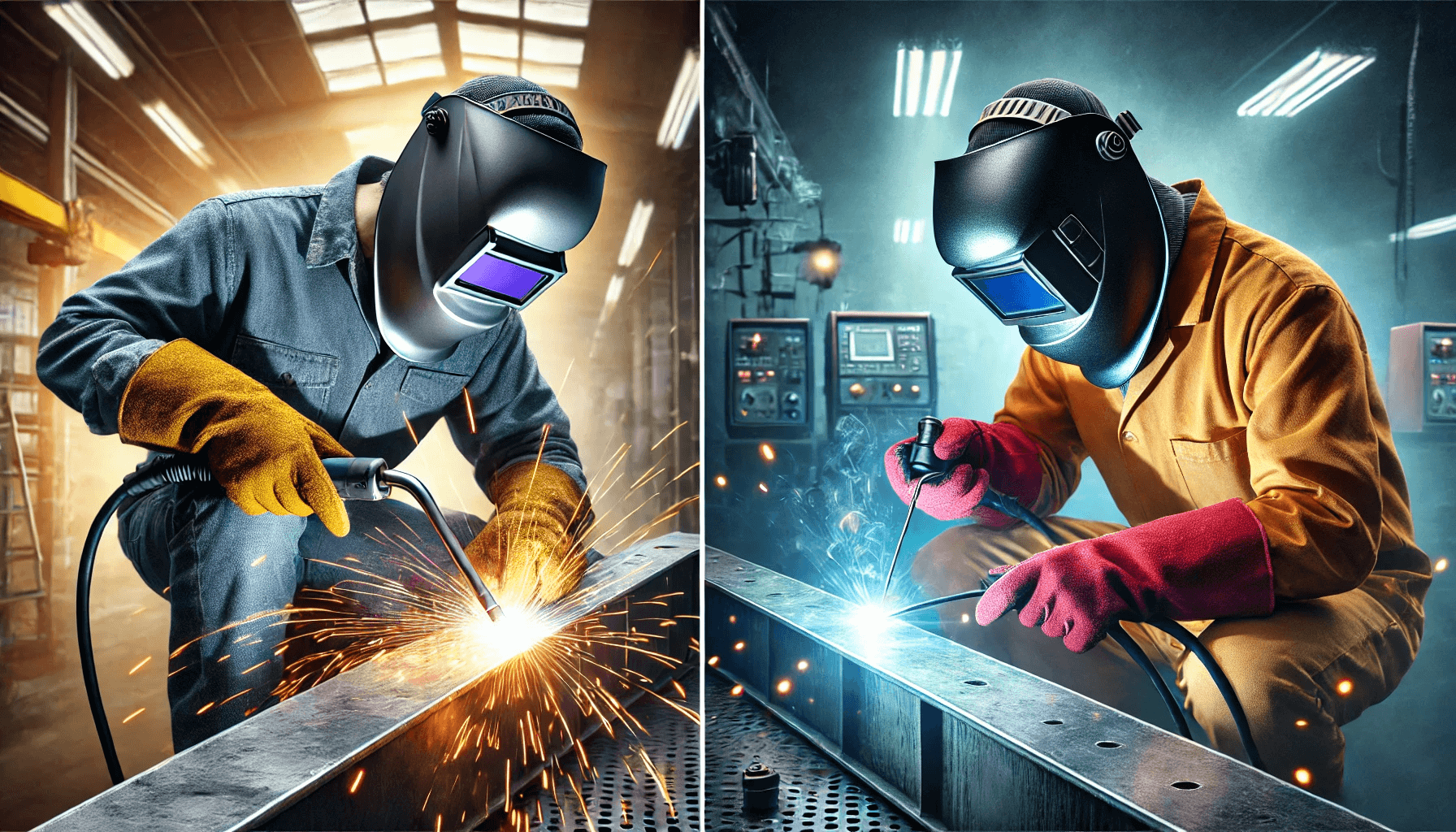

When it comes to welding aluminum, MIG welding vs TIG welding can be a challenging decision for both seasoned professionals and beginners alike. Each process brings its own set of benefits and potential pitfalls, making it essential to understand their key differences. Whether you’re looking for speed, precision, or specific material compatibility, knowing which method to use can significantly impact the quality of your work. In this blog, we’ll take a closer look at MIG welding and TIG welding processes for aluminum, helping you determine the best approach for your next project.

MIG Welding Aluminum: The Process and Considerations

1. Preparation

When it comes to mig welding aluminum, preparation is key. Aluminum is more sensitive than steel, requiring thorough cleaning to remove any lubricants and oxides that could contaminate the weld. A stainless steel wire brush is your best friend here. Additionally, mig welding aluminum is typically suited for materials that are 14 gauge or thicker. If you’re working with thinner materials, consider using a pulsed mig welding machine or even switching to TIG welding machine for better control.

2. Process & Equipment

For mig welding, the process involves using a spray transfer method, which is ideal for aluminum. You’ll want to pair your mig welding machine with a spool gun or a push-pull system to feed the aluminum wire effectively. The choice of filler metal is also crucial; ER4043 and ER5356 are commonly used, depending on the base metal alloy and the specific requirements of the application.

Here’s a quick overview of the equipment and settings you’ll need:

| Equipment/Setting | Details |

| Shielding Gas | 100% Argon at 20-30 CFH |

| Gun and Wire Feeding | Spool Gun or Push-Pull System |

| Filler Metal | ER4043 or ER5356 |

| Travel Angle | 10-15 Degree Push Angle |

| Tip-to-Work Distance | Proper Distance with Recess Contact Tip |

| Beads | Multiple Straight Beads for Larger Fillet Welds |

| Travel Speed | Increase as Material Heats Up |

3. Techniques & Troubleshooting

When it comes to the mig welding process, technique is everything. You’ll need to maintain a 10-15 degree push angle and avoid large weave beads. For larger filet welds, using multiple straight beads is recommended. One of the challenges with mig welding is burn-through, especially with thinner materials. If this happens, increase your travel speed, use shorter welds, or consider switching to TIG welding.

Another common issue is dirty welds, which can be addressed by cleaning the material properly and ensuring you’re using the correct shielding gas and wire alloy. Lastly, to ensure your mig welding process is smooth, always remember to double-check your machine settings, contact tip size, drive rolls, and gun liner.

TIG Welding Aluminum: Precision and Control

1. Why Use TIG Welding for Aluminum?

TIG welding offers precise heat control, which is essential when working with aluminum. This process is particularly suited for those who need to avoid overheating and potential damage to the metal. Additionally, TIG welding provides a wide range of filler metals, allowing you to match the properties of the base metal more closely.

2. Preparing for TIG Welding Aluminum

Before you start TIG welding aluminum, surface preparation is crucial. You’ll need to remove the oxide layer with a dedicated stainless steel wire brush and clean the surface with a solvent to remove any contaminants. The most common shielding gas used is argon, but depending on your specific needs, a mixture of argon and helium might be more appropriate, especially for thicker plates.

When it comes to tungsten selection, pure tungsten is generally good for thin aluminum, while zirconiated tungsten is better for applications requiring high current capacity and a stable arc. The filler rod selection will depend on the base metal; ER4043 is better for high temperatures and crack resistance, while ER5356 is more common for 5000/6000 series aluminum.

3. Techniques and Troubleshooting

TIG welding requires a steady hand and good hand-eye coordination, but with practice, it becomes easier. One of the best practices is to use AC polarity to remove the oxide layer and improve weld visibility. Adjusting balance control can also optimize oxide removal and arc stability. Additionally, adding more filler metal to achieve the stacked-dimes appearance is a common technique among seasoned welders.

To avoid common issues like burn-through, reduce the heat input, adjust the joint design, or use thicker material. Dirty welds can usually be fixed by checking your technique, voltage, and shielding gas. If you’re facing gun issues, maintaining proper tip-to-work distance is key.

MIG vs TIG Welding: Which One Is Better for Aluminum?

When it comes to MIG welding vs TIG welding for aluminum, the choice largely depends on the specific application. MIG welding is faster and better suited for thicker materials, while TIG welding offers more precise control, making it ideal for thinner materials and intricate welds.

Here’s a quick comparison:

| Feature | MIG Welding | TIG Welding |

| Speed | Faster | Slower |

| Material Thickness | 14 Gauge and Thicker | Thin to Medium Thickness |

| Heat Control | Less Precise | Very Precise |

| Ease of Use | Easier for Beginners | Requires More Skill |

| Weld Appearance | Decent, but Less Aesthetic | High-Quality, Aesthetic |

Common Questions About MIG and TIG Welding for Aluminum

1. Is MIG or TIG better for welding aluminum?

It depends on the material thickness and the desired quality of the weld. MIG welding is faster and more suited for thicker materials, while TIG welding offers greater precision and a cleaner finish.

2. Can you MIG weld aluminum?

Yes, you can mig weld aluminum, but it requires the right preparation, equipment, and technique to achieve a quality weld.

3. What are the 3 types of MIG welding?

The three main types of mig welding are short-circuit, globular, and spray transfer.

4. What is considered the best MIG welding machine in Malaysia?

The best mig welding machine in Malaysia will depend on your specific needs, such as material type, thickness, and desired weld quality.

Choosing the Right Welding Supplies: A Crucial Decision

Selecting the appropriate welding supplies is critical to achieving the best results, whether you’re working with aluminum or other materials. When choosing your welding equipment, consider the type of welding process you’ll be using. For mig welding aluminum, ensure that your mig welding machine is compatible with aluminum wire and has the necessary settings for spray transfer. Additionally, look for a machine that offers adjustable voltage and wire speed control to handle various material thicknesses.

On the other hand, if you’re leaning towards TIG welding, prioritize a tig welding machine with precise heat control, AC polarity options, and a range of tungsten electrodes to match your specific needs. Don’t forget to factor in the quality of your filler rods and shielding gas, as these play a significant role in the final weld quality. Investing in high-quality welding supplies from a trusted provider like Hertztec not only enhances your work efficiency but also ensures safety and durability in your welding projects.

Why Choose Hertztec for Your Welding Needs?

At Hertztec, we understand that choosing between MIG welding and TIG welding can be challenging, especially when dealing with aluminum. Our wide range of welding supplies, including mig welding machines, tig welding machines, spot welding machines, and mma welding machines ensures that you’ll find the right tools for any job. Whether you’re a professional welder or just starting, our expert team is here to guide you through every step, ensuring you have the best equipment and support.

Ready to take your welding to the next level? Explore our selection of mig welding machines in Malaysia today, and let Hertztec help you achieve the perfect weld every time.